Cast Iron Manifolds Vs Stainless Steel: Is It Worth Making The Switch To Stainless?

Comparing cast iron manifolds to stainless steel is always a hot topic of debate, and you’ll find opinions vary. One mate will say stainless steel manifolds have transformed the performance and efficiency of his boat, while another will say they are prone to cracking and warping. The truth is there’s cast iron vs stainless, and then there’s different grades of stainless – and not all grades will do the job.

Here we cover off on the key differences between cast iron and stainless, bust some common myths around stainless steel in saltwater, and hopefully help you make an informed decision when it comes to upgrading or replacing your manifolds.

Manifold Design: Cast Iron vs Stainless

First, let’s talk about how each type of manifold is designed.

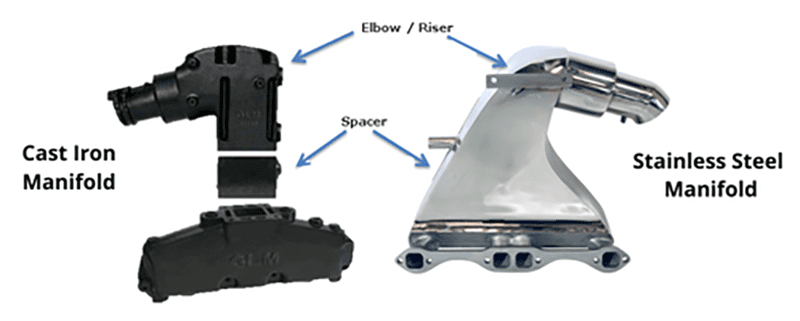

Cast iron manifolds are a multi-piece construction, including joints and gaskets. As the parts expand and contract with heat, the manifold can gradually lose sealing around the gaskets and become prone to leaking, corrosion and worst case scenario- catastrophic engine failure. So why is cast iron used for manifolds? Short answer is the material is inexpensive and easy to work with- ideal for keeping manufacturers’ costs to a minimum.

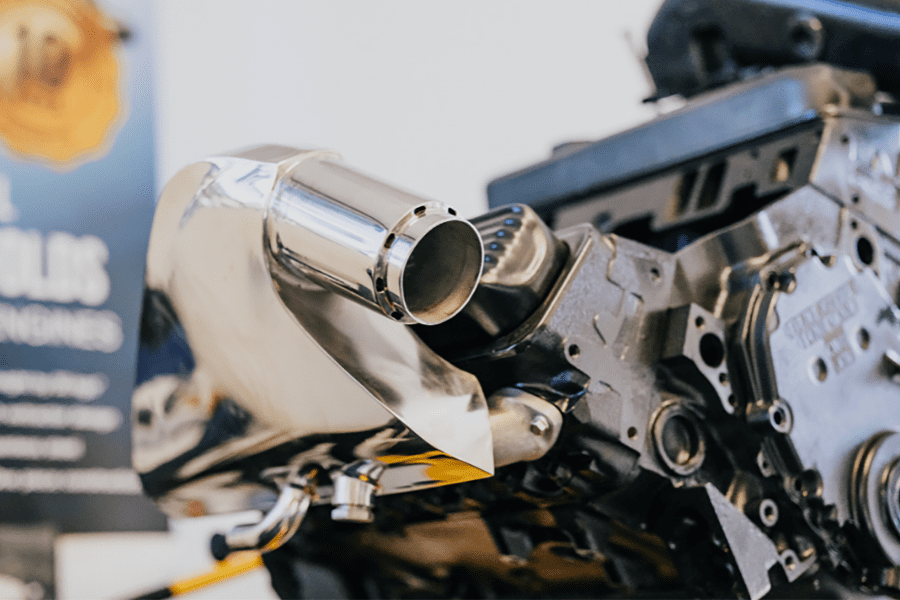

In comparison, MarineTorq’s stainless steel manifolds are a one-piece construction, which includes the spaces, risers and elbow all in one. As there are no joints or gaskets within the manifold design, all risk of gasket failure and leaking is avoided. A water jacket additionally conceals all the internals and provides an extra layer of protection.

Corrosion: Cast Iron Vs Stainless

Cast iron corrodes in a blistering action, which can leave heavy layers of scale up to 1/4 of an inch thick. This thick scale blocks water flow, can cause overheating, and further advances the corrosion process. When left to rust for long periods, the internal walls can deteriorate to the point of irreversible damage. There’s no set expiration date for cast iron manifolds, and internal damage often isn’t evident until it’s too late. The best policy with cast iron manifolds is to periodically remove and inspect them for corrosion, and completely replace them every 3-5 years. Not surprisingly, the time and money spent on maintenance adds up over time, albeit very necessary maintenance to avoid ending up with manifolds like these…

Before we start talking about stainless steel, we know what you’re probably thinking. We hear this question all the time- how does stainless steel not rust in water?

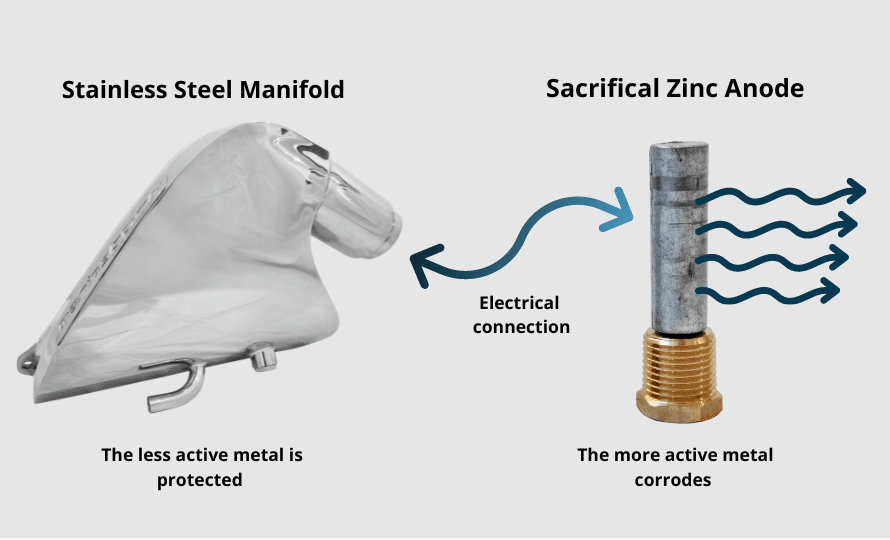

Every MarineTorq manifold includes a sacrificial zinc anode, and as long as this is replaced regularly (we recommend twice a year in salt water), there is no absolutely no chance the stainless steel will corrode. So how do anodes work?

When two metals are immersed in saltwater, they create a current. The current is charged by one of the metals releasing bits of itself in the form of metal ions- known as corrosion. To counter this, a zinc anode adds another metal into the circuit. As zinc is a highly active metal, it corrodes (or sacrifices itself) in place of stainless steel, and the manifold remains in perfect condition.

The simple alternative to replacing cast iron manifolds every few years, a sacrificial anode guarantees years’ worth of service out of a stainless steel manifold. If you find it hard to believe a small piece of metal can make such a difference, the proof is in this comparison shot between a brand new and two rusted anodes. For more info on when anodes should be replaced, why zinc is the best material, and how to order anode replacements, click here.

Weight and Performance: Cast Iron Vs Stainless Manifolds

Cast iron manifolds have extremely thick walls to slow down the corrosion process, which means they can weigh upwards of 50kg. This adds a significant amount of dead weight to the boat, and as a result impacts the power, performance and fuel efficiency. The weight of cast iron also means two people are required to help lug the manifolds out of the engine bay each time they need removing or replacing.

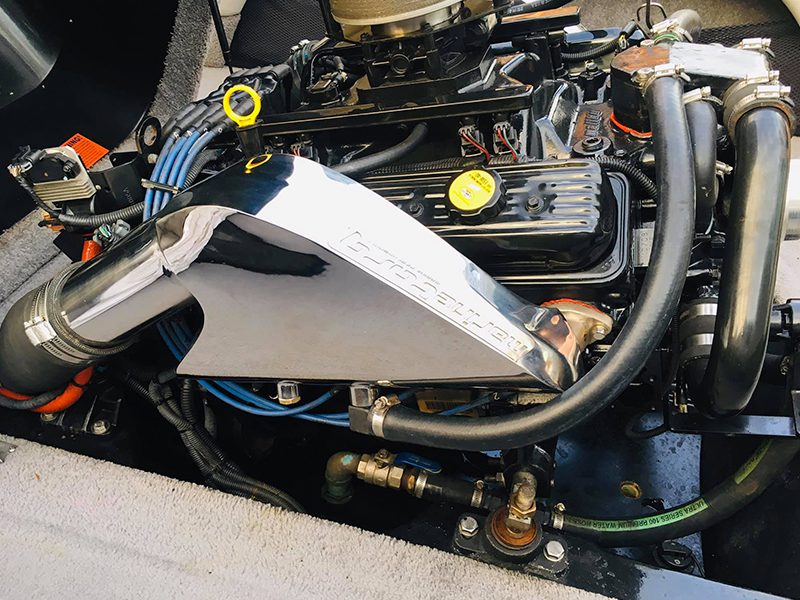

In contrast, a single MarineTorq stainless steel manifold weighs about 7kg on average, reducing your dead weight by up to 80%. Many stainless steel manifold owners notice a significant boost in overall fuel efficiency, power and performance, and find the lightweight design helps the engine run smoother, cooler and more efficiently. Plus, a huge bonus with stainless steel manifolds is they are a one-man job to install. Each MarineTorq manifold comes with a full fitment kit, including a custom bent spanner for easy access in the tight spots. For a detailed insight into the installation process, watch this customer fit a set of stainless manifolds to his 5.0L Volvo Penta…

Manifold Lifespan & Maintenance: Cast Iron Vs Stainless

One of the top reasons for manifold failure is leaky risers, and that’s not surprising given the lifespan of cast iron manifolds can be as short as 2-4 years. Preventative maintenance goes a long way to avoiding larger costs down the track, and with cast iron manifolds keeping on top of this regular maintenance is crucial to avoiding premature failure. Frequent manifold checks and replacements soon become inconvenient and expensive- which is why the ongoing maintenance is one of the top reasons boat owners make the switch from cast iron to stainless.

In comparison, MarineTorq stainless steel manifolds will last in excess of 10 years- one customer has clocked 20 years of saltwater use and is still counting. For total peace of mind against corrosion and manifold failure, all that’s required is routine anode replacement, which we recommend doing twice a year. In comparison to replacing the entire manifold, the initial cost of stainless steel manifolds far outweighs the time, money and labour spent on regular cast iron replacements.

If you need further proof of the extended lifespan of stainless steel, just check out the condition of this manifold, after 9 years of use in saltwater. This customer flushes out his boat after every use, and his regular anode replacement is clearly paying off…

Wait…Do Stainless Steel Manifolds Crack?

It’s a common assumption that stainless steel becomes brittle, and is prone to cracking and warping. Before you swallow this hook, line and sinker, there’s some things to keep in mind.

Firstly, not all grades of steel are designed for the same purpose. Although they may appear identical, each grade has substantial differences in strength, hardness, and resistance to corrosion and pressure. MarineTorq has conducted extensive testing on steel of different grades and thickness, to determine the superior option which is used for all MarineTorq manifolds today. This has been proven to withstand extreme heat and pressure, and is routinely checked and tested as part of our ISO9001 accreditation.

That leads us to our second point- you usually get what you pay for. Poorly manufactured manifolds can easily give stainless steel a bad name, and do not offer good value for money.

At MarineTorq, a patented design is backed up by quality fabrication. Each manifold is made from 2mm thick stainless, which is both MIG and TIG welded, and undergoes several testing procedures before leaving our factory. Check out water pressure testing in action on a set of stainless manifolds for a GM LS small block engine here.

And lastly, if you’re still not convinced on the longevity of stainless steel, MarineTorq boat manifolds are backed by a 10 year warranty, and our jet ski manifolds by a 5 year warranty. To find out exactly what this warranty covers, click here.

Stainless Steel Boat Manifolds: View Your Options Today

Stainless steel manifolds are more than a consumable item on your boat. They’re a long-term solution which yes, may cost more initially, but it only takes a few years of cast iron replacements before you’ve exceeded the one-time cost of stainless.

Remember with cast iron manifolds, internal damage may not be evident until it’s too late. Making the switch to stainless steel manifolds is a no-brainer for reducing your replacement intervals, maintenance costs, and giving you total peace of mind from any threat of engine failure.

Check out the stainless steel manifold options for your boat here, or fill out the below form to speak to our Marine experts and get your quote today.