Find a Dealer

MarineTorq has an extensive dealer network both in Australia and internationally. Find your nearest dealer by clicking here.

View locationsCan’t find your manifold? Click here to request for a manifold.

Reduce maintenance costs, prevent leaky risers, and improve your boat’s performance

View range $3,690.00 AUD

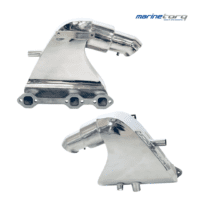

Mercruiser 4.3L V6 Exhaust Manifold

$3,690.00 AUD

Mercruiser 4.3L V6 Exhaust Manifold

$3,690.00 AUD

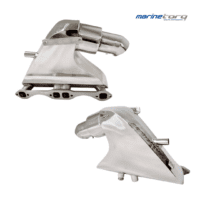

Mercruiser 5.7L V8 MAG MPI Exhaust Manifold: 2003 – 2018

$3,690.00 AUD

Mercruiser 5.7L V8 MAG MPI Exhaust Manifold: 2003 – 2018

$3,690.00 AUD

Indmar 5.7L V8 Exhaust Manifold

$3,690.00 AUD

Indmar 5.7L V8 Exhaust Manifold

The one piece construction eliminates all joints and gaskets, preventing leaking and likelihood of engine failure

Cast Iron manifolds weigh upwards of 50kg. In comparison, MarineTorq manifolds weigh 7kg on average, reducing your boats dead weight by up to 80%

All MarineTorq manifolds use 2mm thick stainless steel, which compared to cast iron is more lightweight, rust resistant, and proven to last

A replaceable zinc anode prevents corrosion and protects the manifold. We recommend replacing these every six months to keep the manifold in optimum condition

We work with you to customise your manifold, including brackets, sensors, risers, spacers and more

A large water jacket securely covers the internals of the manifold, improves the cooling process, and adds an extra layer of protection

By reducing dead weight and improving the manifold’s efficiency, a MarineTorq manifold can provide significant fuel savings and an increase in power and performance

MarineTorq’s superior manifold design allows us to offer a 10 year warranty for boat manifolds, and a 5 year warranty for jetski manifolds

MarineTorq has an extensive dealer network both in Australia and internationally. Find your nearest dealer by clicking here.

View locationsClick here to learn more about our patented Stainless Steel Manifolds

Browse SupportReplace your cast iron manifolds to prevent engine failure, and increase your boat’s power and performance with stainless steel!

Browse ProductsExplore how stainless steel manifolds can transform your vessel.

View Catalogue

Subscribe to our mailing list and receive 5% OFF your next order or Manifold Care Kits